Using manual order picking correctly in logistics

Info

Manual order picking is a central component of logistics processes in many companies. This involves picking specific items from the warehouse based on customer orders. Despite the growing popularity of automated systems, manual processes remain relevant for various reasons, even with serialised picking, for example due to the flexibility they offer or when processing smaller orders.

However, manual picking is associated with a number of challenges. These include, for example:

- Increasing complexity of orders due to increasing product variants and customised requirements.

- Susceptibility to errors and the resulting quality problems.

- Time and costs, especially with order-orientated picking.

- Stress on employees due to monotonous, physically strenuous activities.

These challenges can significantly affect the efficiency and productivity of manual order picking. Many companies are therefore faced with the task of optimising their processes with suitable solutions.

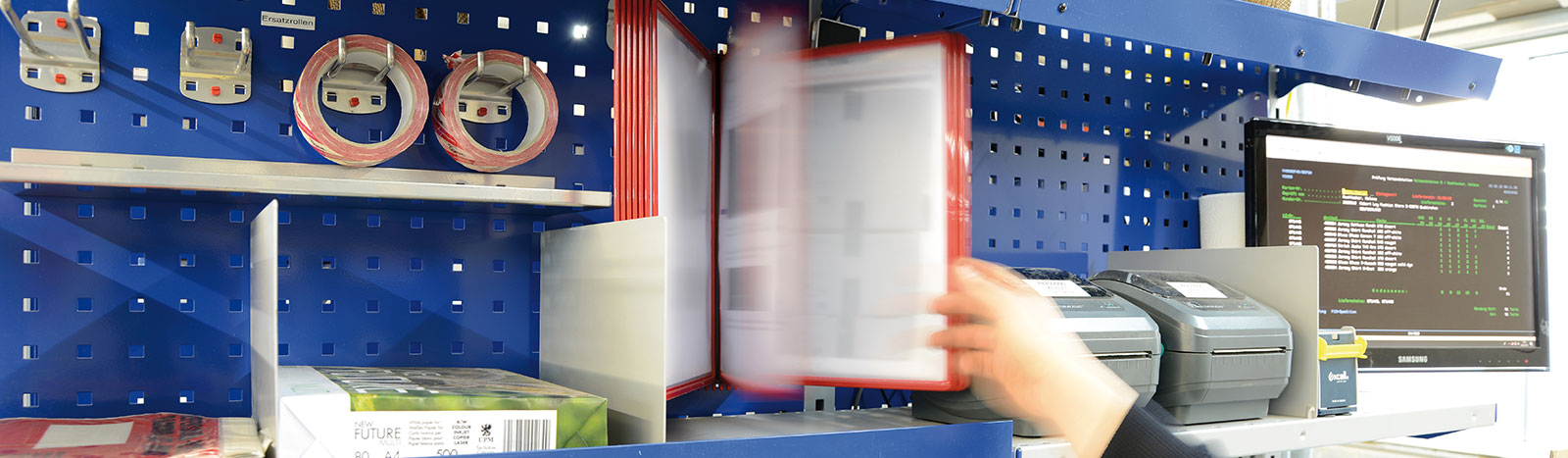

Rocholz has set itself the task of offering employers opportunities to overcome the obstacles of manual order picking. This includes not only ergonomic workstation design, such as our SYSTEM FLEX, but also the appropriate expansion of such logistics workstations with assistance systems. We will show you how you can optimise manual order picking in your company.

Dealing with complex tasks

The increasing individualisation of products and varying customer requirements increase the complexity of manual picking tasks. Each order can include different items, quantities and special packaging or delivery requirements. This variability can make it difficult to achieve consistently high performance and increases the risk of errors.

One solution that is proving particularly effective in this context is digital picking aids. One example of this is the Simple Assist assistance system from Rocholz. It is a plug & produce system that supports employees with simple visual instructions. By projecting the work steps directly onto the work surface, employees are optimally guided in their activities.

On the one hand, this reduces the familiarisation time and error rate, and on the other, it promotes self-determined and ergonomic working. The advantages of Simple Assist include:

- Stand-alone assistance system without interface to other systems.

- Can be set up, operated and run without IT knowledge.

- Create work instructions easily with MS PowerPoint®.

- Ergonomic, self-determined working with digital guidance.

- Self-explanatory system, no training required.

- Elimination of errors through precise instructions.

With digital assistance systems of this kind, companies can overcome the challenges of complex manual picking processes and increase their efficiency.

Product customisation and a wide range of variants

The growing individualisation of products and diversity of variants brings with it a number of challenges for manual picking. As individualisation and variety increase, so does the complexity of picking tasks. This places high demands on the skills and knowledge of employees and can increase the risk of errors and inefficiencies.

In addition, the individualisation of products leads to complex value-added services. These services, such as customised packaging or special processing of articles, require additional expertise and skills from employees.

In such cases, the AssisTable assistance system from Rocholz can be an effective solution. AssisTable serves as a digital work catalogue that supports employees in their picking and packing processes. The system displays the individual work steps in detail and with images, allowing even more complex requirements to be implemented efficiently and error-free. AssisTable offers:

- Simple realisation of complex value-added services.

- Self-determined work despite product individualisation and a wide range of variants.

- Server-based system that can be used regardless of location.

- Automatic generation of economic key figures through digitalisation.

AssisTable enables companies to successfully master the challenges of product customisation and increase the efficiency and quality of their manual picking processes.

Quality assurance and error detection

Another critical aspect of manual picking is quality assurance, in particular the early and reliable detection of errors. Errors can lead to quality problems, affect customer satisfaction and cause additional costs for returns and recovery tasks.

Frequent sources of error usually relate to incorrect articles, incorrect quantities or unsuitable packaging. Accordingly, recognising these errors at an early stage is an essential prerequisite for efficient and high-quality manual picking.

The InspecTable assistance system from Rocholz can make a valuable contribution here. InspecTable is an image-based system that performs a comparison with the trained target situations and can analyse individual items and their position as well as the overall picture. The advantages of InspecTable include

- Zero defects thanks to visual inspection.

- Flexible system that is simply trained for the application.

- Visualisation of different states and key figure for hit probability.

- Intelligent system that learns independently through continuous use.

With solutions such as InspecTable, companies can maintain their quality standards in manual order picking and improve their process efficiency at the same time.

Documentation and identification

Precise documentation and identification of parcel contents play a crucial role in manual order picking. It enables the seamless tracking and verification of consignments, which increases the transparency of the process and minimises sources of error. Detailed recording also makes it easier to process returns and complaints.

Despite the importance of documentation and identification, these tasks can often be neglected in the hectic daily routine of order picking. The consequences are insufficient transparency, difficulties in tracking consignments and increased time and effort in clarifying discrepancies.

This is where the DocumenTable assistance system from Rocholz can provide support. With DocumenTable, companies can easily create photos for documentation directly at the logistics table in dispatch or goods receipt. All the data generated can be clearly assigned and retrieved via the network. DocumenTable offers the following advantages:

- Integrated photo documentation of parcel contents.

- Clearly assignable data storage.

- Transfer to own server structure via LAN, connection to own ERP system possible.

- All-in-one solution without follow-up costs.

With solutions such as DocumenTable, companies can optimise their manual picking processes and thus increase their efficiency and customer satisfaction.

Optimise your manual order picking with Rocholz

Regular optimisation of your manual order picking is crucial to remain competitive and continuously increase sales. By simplifying complex tasks, using digital assistants, implementing solid quality assurance and accurately documenting processes, you can optimise your order picking work steps and make them more efficient.

The assistance systems from Rocholz Simple Assist, AssisTable, InspecTable and DocumenTable are designed to help you with precisely these aspects. Our experts will be happy to assist you if you have any further questions about the products.