Optimise material flow and increase production effectively

Tips

In today's business world, optimising the flow of materials is essential in order to be able to produce efficiently and on time. This not only saves storage costs, but also allows more goods to be produced in the same amount of time. An effective material flow enables smooth production and logistics, reduces costs and increases customer satisfaction. Read this article to find out how you can optimise your material flow to make your company more efficient and competitive.

This is why optimising the material flow is so important

Companies of all sizes need to optimise their material flow. This is the only way to speed up production processes and achieve greater overall efficiency. A well-organised material flow leads to faster throughput times, higher productivity and less storage space is required. As a result, order processing is faster and customer satisfaction is higher when you optimise your material flow.

The first step towards optimising the material flow

The process of optimising the material flow begins with a comprehensive analysis of the current status quo. It is crucial to recognise inefficiencies, bottlenecks and unnecessary work steps. Key questions of typical analyses for the current state look something like this:

- What is the current material flow?

- Which storage areas are utilised or unused?

- Is there a lack of material or parts for production or is there too much?

- Is there enough trained staff on site to get the job done on time?

- Are employees well enough informed about the work processes?

- Is co-operation with suppliers and partners on schedule?

Once you have found answers to questions like these, you should draw up a customised improvement plan to optimise your material flow. This must be tailored to the specific requirements of your company. You should always have an idea of how the supply chain, warehousing and internal processes interact. This is the only way to optimise the material flow. Use data and feedback from employees to get an accurate idea of all relevant processes.

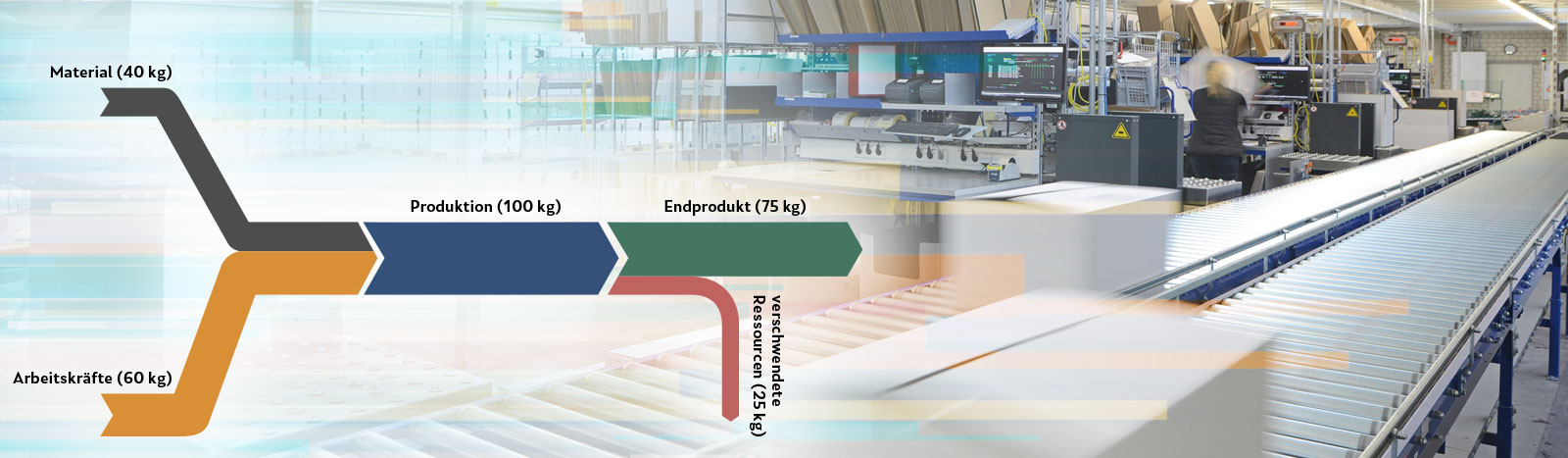

Expert tip: Use the Sankey diagram

A Sankey diagram is a specific type of flowchart that is mainly used to visualise resource, material or cost flows. The width of the arrows or lines in the diagram is proportional to the amount of material or energy flowing, effectively visualising where resources are produced, consumed and lost.

Identify solutions and implement them efficiently

The key to optimising material flow lies in minimising waste and maximising efficiency in all areas of the material flow. From the delivery of resources to the dispatch and sale of the finished product must be covered by a detailed optimisation plan.

To make implementation easier, Rocholz has developed a range of assistance systems to support your employees. By integrating these assistance systems into the work process, companies can optimise their material flow. You too can benefit from these advantages:

- Quality control and reduction of errors: Systems such as InspecTable can recognise errors in packaging and picking processes at an early stage. This prevents errors and improves product quality. The material flow is optimised by reducing returns and reworking.

- Effective work instructions: Systems such as SimpleAssist and AssisTable provide clear, visual work instructions that increase employee efficiency. Employees can work faster and more effectively thanks to precise instructions, which can further optimise and therefore speed up the material flow. Training new employees is also much quicker and easier.

- Recording of data and processes: AssisTable enables work processes and quantities to be recorded and analysed. This information can be used for more effective planning and control of the internal material flow, particularly in relation to the calculation of capacities and the resource management of Industry 4.0.

- Documentation and traceability: The packaging process can be recorded with DocumenTable, which enables complete traceability. This is particularly important for quality control and audit purposes. The data obtained is also a suitable solution for optimising the material flow more easily.

- Adaptability to different processes: The flexibility of the systems, particularly InspecTable with its machine learning capability, allows them to be customised to different products and processes. As a result, they can be used in different areas of the material flow to increase efficiency.

- Reduction in training time: Assistance systems from Rocholz are user-friendly and easy to understand, which shortens the familiarisation time for new employees. This enables an efficient material flow and leads to faster integration into the work process. This is a massive advantage if you want to optimise your material flow, especially in times of a major shortage of skilled workers.

The ergonomic workplace and material flow

Rocholz has yet another idea for optimising your material flow. With our advanced concepts, we offer you the opportunity to take action through ergonomic workplace design. The ergonomic design of our products not only improves the quality of your employees' work, but also promotes health and satisfaction.

Our customised packing tables enable employees to work in a comfortable and healthy working environment. This increases productivity and efficiency, which also optimises the flow of materials. Every workplace is unique and requires customised solutions that are tailored to the specific needs of your company.

An ergonomic workplace is the ideal solution for reducing sickness rates and thus conserving resources from the employer's perspective. If employees are absent, the employer has to spontaneously reallocate resources and work tasks. This in turn costs time and reduces the efficiency of the existing system. By using ergonomic workstations, the material flow can be optimised in a targeted manner, as they give the system a certain degree of security. Fewer breakdowns also mean that fewer risk factors threaten and disrupt the material flow.

Measure success, react promptly

Optimising the material flow is a continuous process that requires creativity and adaptability. To evaluate the success of the optimisation measures, clear KPIs (key performance indicators) must be defined and measured regularly. This facilitates the monitoring of progress and possible adjustments.

What are key performance indicators (KPIs)?

KPIs are measurable values that show how effectively a company is achieving important business objectives or operational goals at the time of measurement. They help to evaluate and track the success of your activities in various areas. This makes it easier to make better decisions and continuously optimise the material flow.

By defining clear KPIs, the results of which you measure and evaluate regularly, you can develop your own strategies for the first time.

Now you know how to effectively optimise your material flow and prepare your company for future challenges. Work with the right strategies and technologies.

Take the opportunity now and benefit from partnerships with companies like Rocholz. Our experts will be happy to advise you on how to ergonomically design your employees' workstations and thus optimise the material flow.