"The new work islands create structure, short distances and noticeable relief in everyday working life."

Project summary

The islands of ergonomics

Spiggle & Theis GmbH (spiggle-theis.com) specialises in the development, manufacture and distribution of medical ENT products. Over the past 30 years, the company has established itself as a specialist in the field of head and neck surgery. When manufacturing medical products, special quality, reliability and precision are required - this also applies to the picking, packaging and dispatch of the products. Spiggle & Theis is based in Overath, close to our distribution partner Dajapac (dajapac.de) in Rösrath, which was entrusted with the task of optimising logistics as a regional player by Spiggle & Theis.

After discussing the customer's ideas, Dajapac suggested a visit to the Rocholz GmbH showroom in Velbert so that they could see and understand what packaging workstations can achieve in logistics. This appointment was organised at short notice and sales partners and end customers were able to experience the Rocholz product range up close and try it out for themselves. Spiggle & Theis was fascinated by the diverse possibilities of our SYSTEM FLEX logistics workstation. SYSTEM FLEX is ideal for customers who want unlimited flexibility and quickly customisable ergonomics and combines all processes into a holistic system.

The customer's premises, processes and requirements were analysed in detail. When planning a logistics workstation, all interrelated processes are harmonised. The focus here was on individual adaptability. As a manufacturer of high-quality medical technology products, Spiggle & Theis sees its task as promoting health - also among its own employees. Accordingly, the customer immediately understood the importance of ergonomics in workplace equipment and wanted all-round ergonomic equipment - as seen in the Rocholz showroom. Based on perspective sketches and explanations, the customer received our proposal and ordered the workstations straight away.

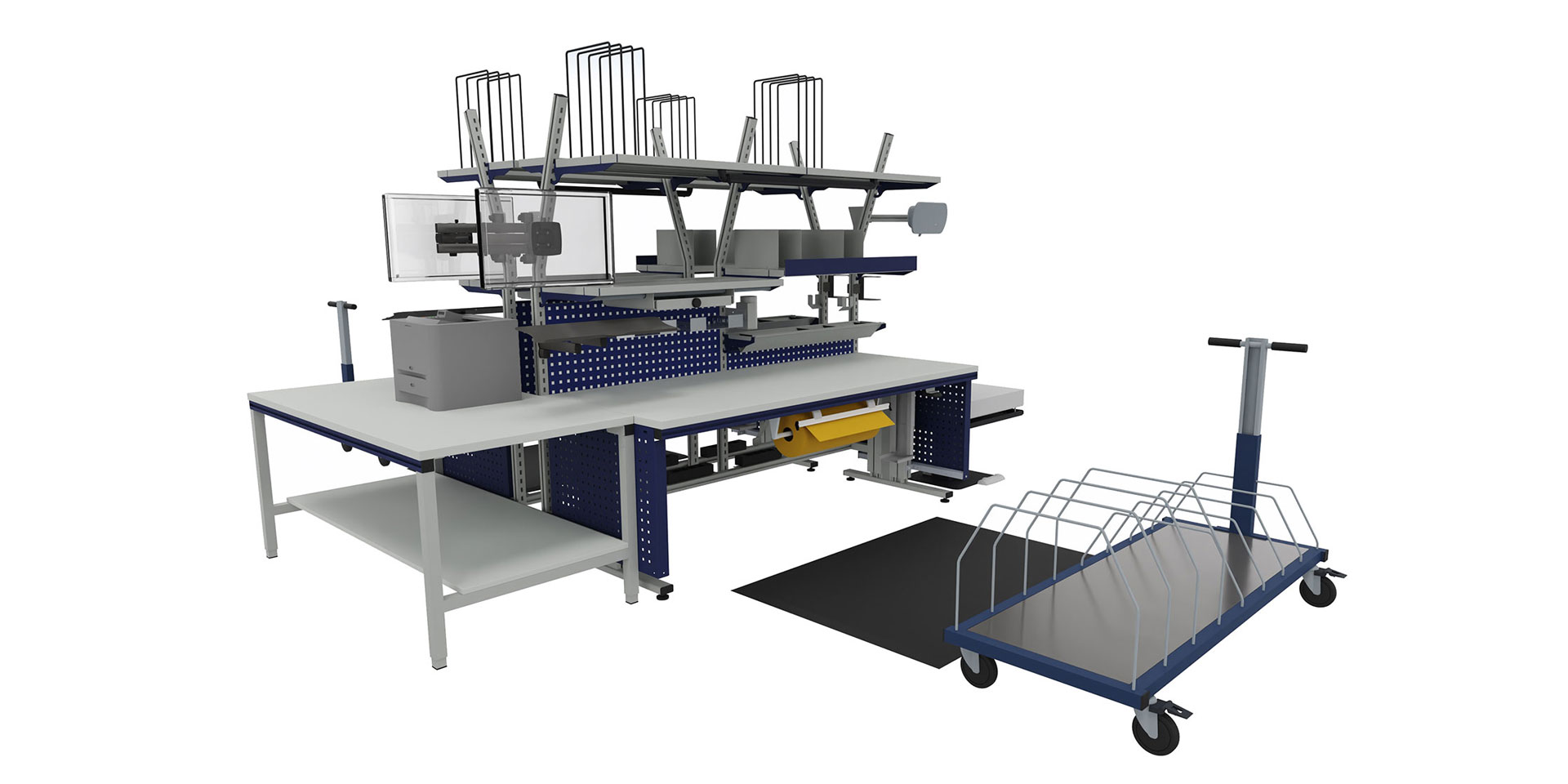

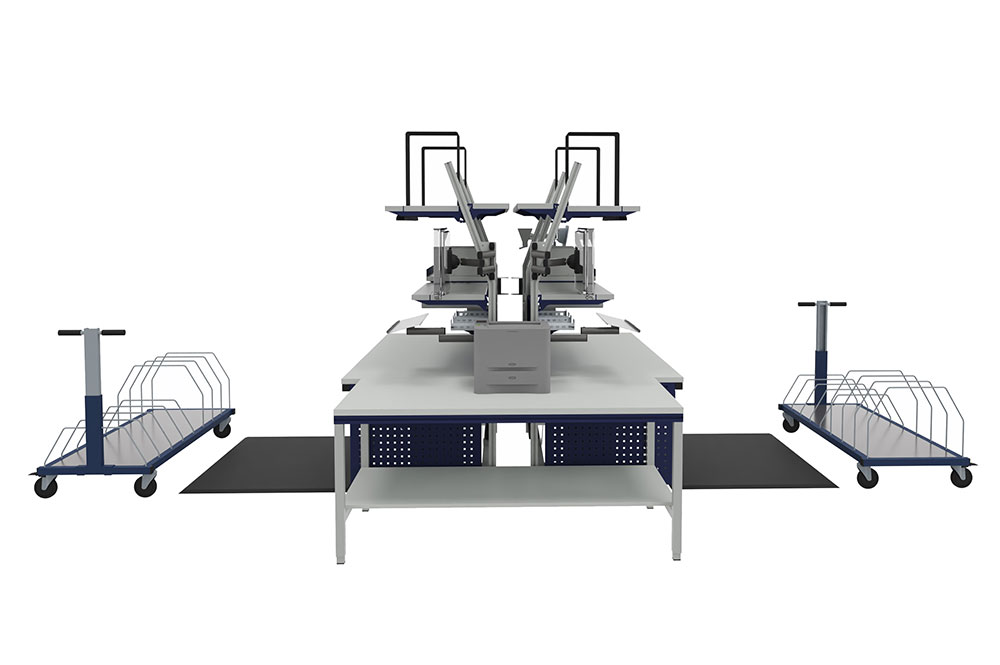

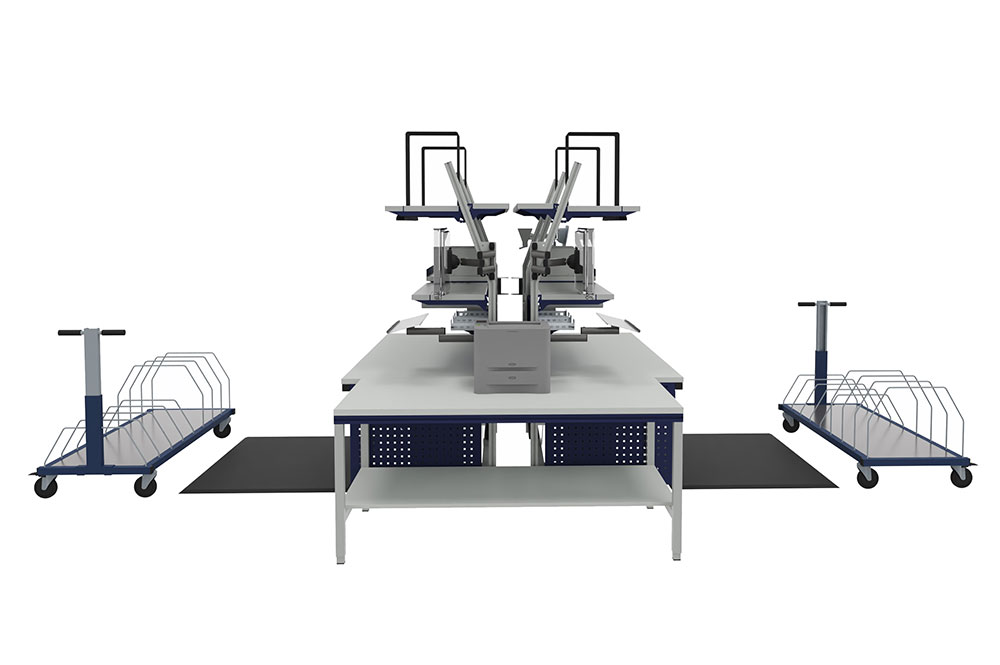

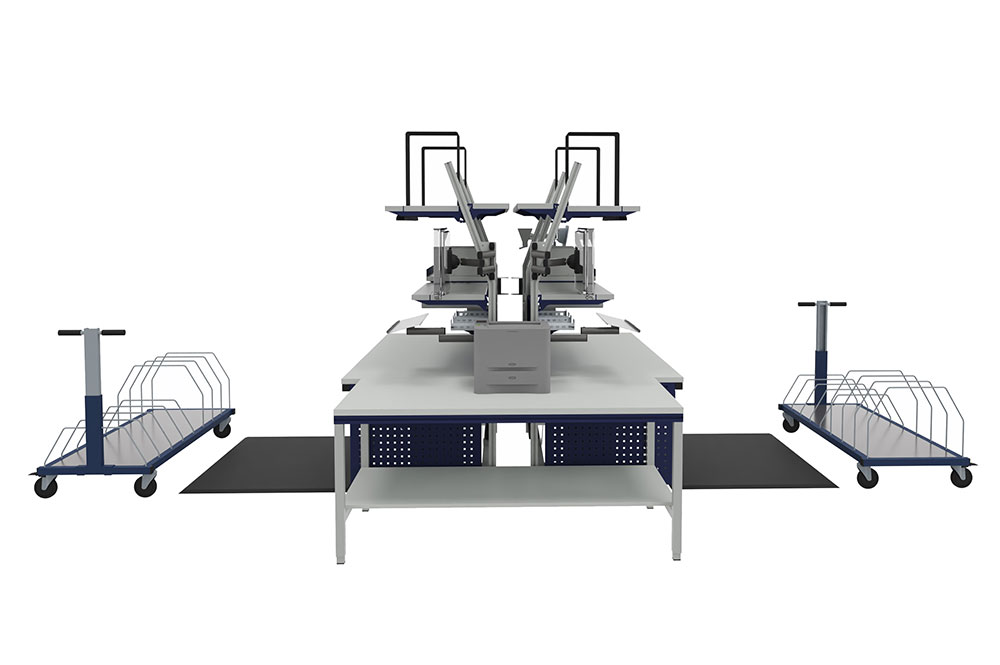

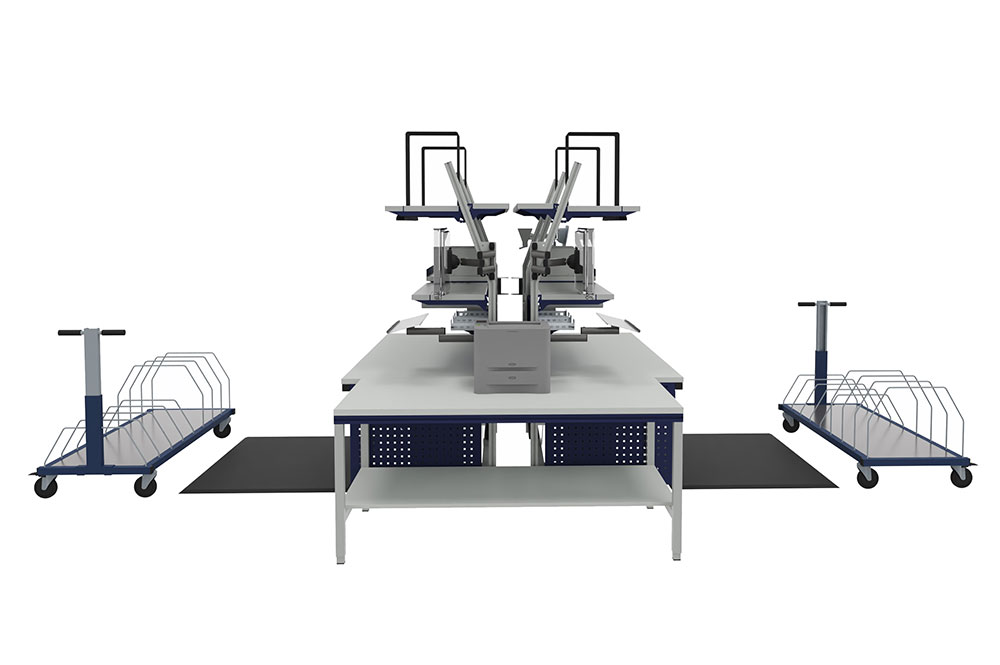

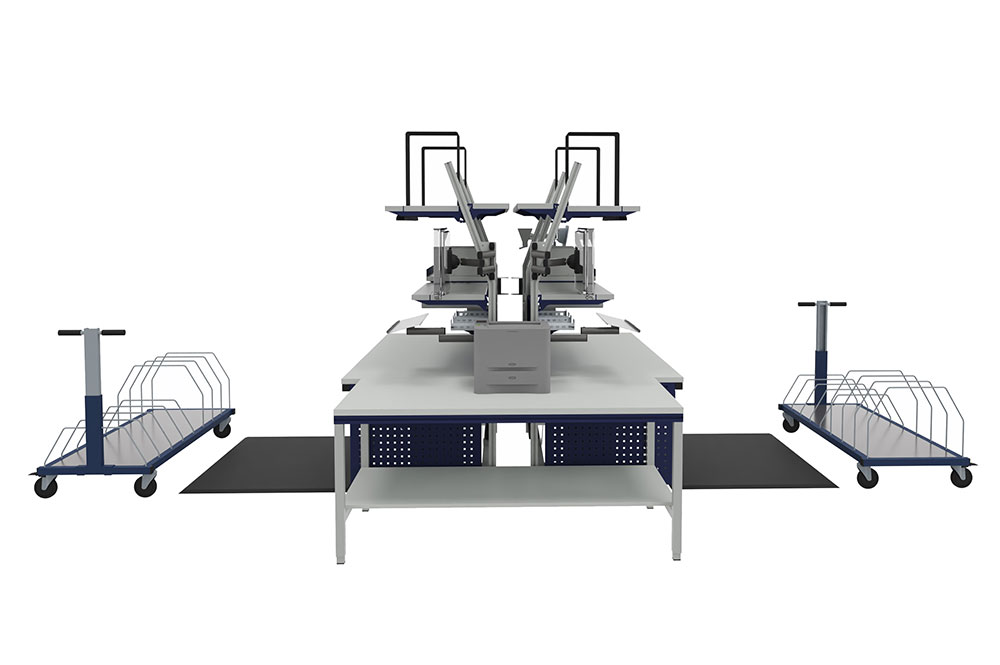

Four identical packing tables were created, each facing each other in pairs and thus forming a double workstation, a side table for additional work and four individual lifting tables, from which the packed goods are palletised directly next to each other on a scissor lift truck. The two permanently integrated groups are supplemented by mobile carton magazines with handles, which can also be stored under the table.

The double workstations opposite each other consist of a SYSTEM FLEX packing table with electric height adjustment, which enables quick adjustment to any body size and any process. Rocholz profiles, which are inclined at the top, guarantee ergonomic gripping spaces when gripping the cartons on top. The more favourable angle makes work considerably easier and at the same time ensures tighter processes. With perforated back panels and various flexible and customisable holders and shelves for IT, tools and materials, every employee can adjust their workstation to suit their needs and the processes involved. Bottle holders, ergonomic lighting and workplace mats that are easy on the spinal discs and joints round off the ergonomic equipment and a dispenser for packaging material has been integrated directly under each packing table, which employees can access quickly and ergonomically.

A single modular SYSTEM FLEX packing table (without Rocholz profiles, without attachments) can be used as a side table at the front of the opposing double workstations for ancillary activities that support the packing processes. On the opposite end of the side tables, two lifting tables attached to the floor complete the work islands. These include an additional function as an individual speciality: the lifting tables integrate a scale at the top and thus combine two processes in a space-saving, ergonomic and efficient way. Crush protection has been added to both sides of the packaging units to ensure work safety.

The medical technology specialist chose us primarily because of our ergonomics expertise, which he was able to experience on site. The ergonomic work islands form a well thought-out logistics work structure that increases the efficiency of Spiggle & Theis GmbH. Thank you very much!

Spiggle & Theis Medizintechnik GmbH

Spiggle & Theis Medizintechnik GmbH

Burghof 14

51491 Overath

2 double workstations set up

Customisable work

Electrically height-adjustable SYSTEM FLEX packing tables with ergonomic gripping spaces support healthy and flexible working.

Two functions, one handle

Lift tables with integrated scales combine lifting and weighing for space-saving, efficient processes.

Material stowed within easy reach

STANDARD undertable dispensers and SYSTEM undertable storage racks ensure quick access and clean organisation at the workplace.

Holistic ergonomic thinking

Workplace mats, lighting and supports ensure that work is ergonomic throughout.

|

|

|

|

|

|

|

|

|

|

|

|

The islands of ergonomics

Spiggle & Theis GmbH (spiggle-theis.com) specialises in the development, manufacture and distribution of medical ENT products. Over the past 30 years, the company has established itself as a specialist in the field of head and neck surgery. When manufacturing medical products, special quality, reliability and precision are required - this also applies to the picking, packaging and dispatch of the products. Spiggle & Theis is based in Overath, close to our distribution partner Dajapac (dajapac.de) in Rösrath, which was entrusted with the task of optimising logistics as a regional player by Spiggle & Theis.

After discussing the customer's ideas, Dajapac suggested a visit to the Rocholz GmbH showroom in Velbert so that they could see and understand what packaging workstations can achieve in logistics. This appointment was organised at short notice and sales partners and end customers were able to experience the Rocholz product range up close and try it out for themselves. Spiggle & Theis was fascinated by the diverse possibilities of our SYSTEM FLEX logistics workstation. SYSTEM FLEX is ideal for customers who want unlimited flexibility and quickly customisable ergonomics and combines all processes into a holistic system.

The customer's premises, processes and requirements were analysed in detail. When planning a logistics workstation, all interrelated processes are harmonised. The focus here was on individual adaptability. As a manufacturer of high-quality medical technology products, Spiggle & Theis sees its task as promoting health - also among its own employees. Accordingly, the customer immediately understood the importance of ergonomics in workplace equipment and wanted all-round ergonomic equipment - as seen in the Rocholz showroom. Based on perspective sketches and explanations, the customer received our proposal and ordered the workstations straight away.

Four identical packing tables were created, each facing each other in pairs and thus forming a double workstation, a side table for additional work and four individual lifting tables, from which the packed goods are palletised directly next to each other on a scissor lift truck. The two permanently integrated groups are supplemented by mobile carton magazines with handles, which can also be stored under the table.

The double workstations opposite each other consist of a SYSTEM FLEX packing table with electric height adjustment, which enables quick adjustment to any body size and any process. Rocholz profiles, which are inclined at the top, guarantee ergonomic gripping spaces when gripping the cartons on top. The more favourable angle makes work considerably easier and at the same time ensures tighter processes. With perforated back panels and various flexible and customisable holders and shelves for IT, tools and materials, every employee can adjust their workstation to suit their needs and the processes involved. Bottle holders, ergonomic lighting and workplace mats that are easy on the spinal discs and joints round off the ergonomic equipment and a dispenser for packaging material has been integrated directly under each packing table, which employees can access quickly and ergonomically.

A single modular SYSTEM FLEX packing table (without Rocholz profiles, without attachments) can be used as a side table at the front of the opposing double workstations for ancillary activities that support the packing processes. On the opposite end of the side tables, two lifting tables attached to the floor complete the work islands. These include an additional function as an individual speciality: the lifting tables integrate a scale at the top and thus combine two processes in a space-saving, ergonomic and efficient way. Crush protection has been added to both sides of the packaging units to ensure work safety.

The medical technology specialist chose us primarily because of our ergonomics expertise, which he was able to experience on site. The ergonomic work islands form a well thought-out logistics work structure that increases the efficiency of Spiggle & Theis GmbH. Thank you very much!